Instructions for using automatic pallet jack

Instructions for using automatic pallet jack

Pallet Jack Instructions

Pallet jacks are an essential piece of equipment in many warehouses and factories. Knowing how to properly use a pallet jack is critical for the safe and efficient movement of goods from one place to another. This article provides a comprehensive guide on pallet jack instructions, outlining the various components, operating procedures, and maintenance tips. Whether you are a beginner or experienced user of pallet jacks, this article will provide useful information that can be used in any warehouse setting.

How To Operate Electric Pallet Jack

Electric pallet jacks are incredibly useful tools for lifting and transporting pallets of goods within warehouses or other facilities. They offer a much safer and more efficient alternative to manual pallet jacks without compromising on maneuverability. In this article, we will provide you with an overview of how to operate electric pallet jacks safely and correctly.

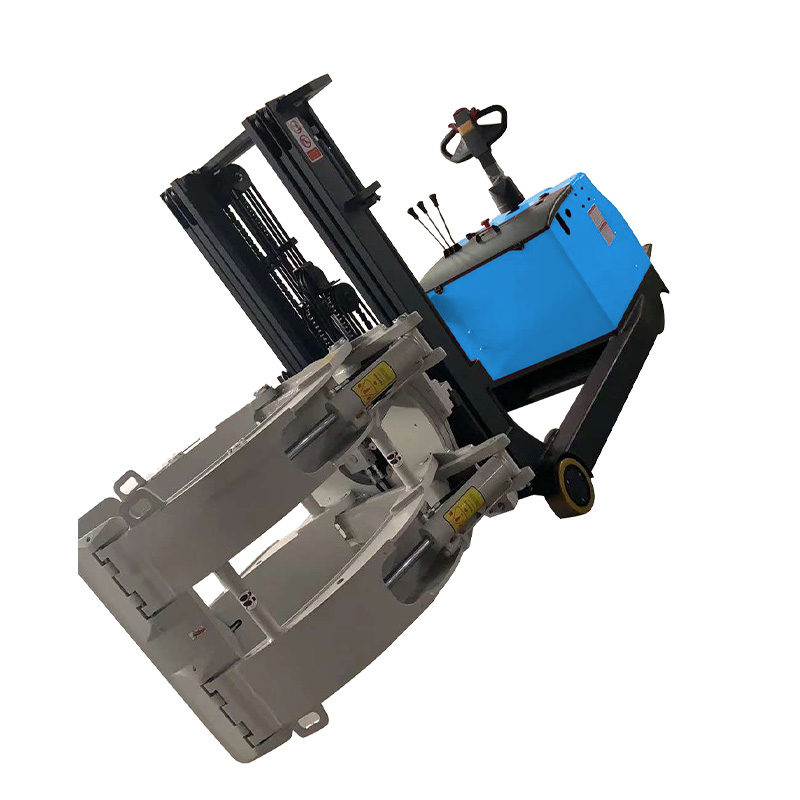

1. Introduction for automatic pallet jack

An automatic pallet jack, also known as a lift truck, stacker truck, or forklift, is a type of powered industrial truck used to move heavy loads from one place to another. The automatic pallet jack is operated by a control handle that the operator holds while walking behind the unit. The operator does not need to sit on the unit or use any type of steering wheel. The automatic pallet jack is powered by a battery, which is located in the base of the unit. The battery provides power to the drive motors that move the wheels.

2. How to Use an Automatic Pallet Jack

The first step in using an automatic pallet jack is to charge the battery. This can be done by plugging the charger into a wall outlet and connecting it to the battery terminals on the unit. Once the battery is fully charged, you can begin using the pallet jack.

To operate the unit, simply squeeze the trigger on the control handle. This will cause the drive wheels to begin moving forward. To stop the unit, release the trigger and allow it to return to its original position. To turn left or right,

If you are looking for an application guide for your automatic pallet jack, you have come to the right place. This article will provide you with all the information you need to know about choosing the right application guide for your needs.

Notes on using automatic pallet jack

If you are thinking of using an automatic pallet jack in your business, there are a few things you should know. Here are some notes on using automatic pallet jack:

1. Make sure that the area where you will be using the automatic pallet jack is clear of obstacles. This will help prevent accidents.

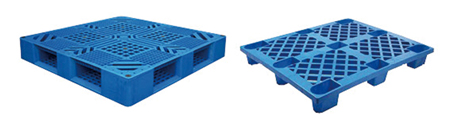

2. When loading or unloading a pallet, make sure that the pallet is level. This will help prevent the pallet from tipping over.

3. Be careful when moving the automatic pallet jack around corners. This is because the wheels can get caught on objects and cause the pallet jack to tip over.

4. Make sure that you always use the proper safety equipment when operating the automatic pallet jack. This includes gloves, safety glasses, and a safety helmet.

It is very important to know how to use an automatic pallet jack properly in order to avoid any accidents. Here are some tips on using an automatic pallet jack:

- Make sure that the area around the pallet jack is clear and free of obstacles before beginning to use it.

- Always wear proper safety gear, including gloves and closed-toe shoes, when using the pallet jack.

- Never try to move a load that is too heavy for the pallet jack or yourself.

- Be careful when moving the pallet jack around corners or through doorways, as its large size can make it difficult to maneuver.

- Once you have finished using the pallet jack, always put it back in its proper place so that it is ready for the next person to use.

How to use self loading pallet jack

Using a self-loading pallet jack is an easy and efficient way of transporting goods from one place to another. This type of equipment eliminates the need for liftgates, ramps, hoists and conventional pallet jacks.

It is easy to operate: simply load the cargo into the van, truck, or delivery vehicle and pull the support. The self-loading stacker then climbs into the vehicle itself, using the same space as a hand pallet. Self-loading forklifts come in a variety of forms, depending on the type of forklift needed. Platform stackers and work positioners, self-propelled pallet trucks, floor level loaders are all available.

With this machine, it is possible to easily handle 1000kg heavy pallets and load them onto a delivery truck. It is important to consider its total weight when moving it around.

How to choose automatic pallet jack

The following tips will help you choose the right automatic pallet jack for your needs:

1. Choose the right size

2. Consider the load capacity

3. Think about the terrain

4. Choose the right type of drive system

If you are working in a warehouse or any other type of business that requires you to move heavy objects around, then you know that an automatic pallet jack can be a lifesaver. But how do you choose the right one for your needs? Here are a few tips:

- Consider the weight capacity. This is probably the most important factor to consider when choosing an automatic pallet jack. You need to make sure that it can handle the weight of the objects that you will be moving around.

- Consider the size. Another important factor to consider is the size of the automatic pallet jack. You need to make sure that it is small enough to maneuver around in your work space, but large enough to handle the objects that you need to move.

- Consider the price. Automatic pallet jacks can range in price from a few hundred dollars to several thousand dollars. You need to find one that fits within your budget while still providing the features and benefits that you need.

Electric Forklift Manufacturers

The electric forklift is an important piece of industrial equipment used in many warehouses and factories around the world. It significantly increases productivity, safety, and efficiency for a variety of different tasks. As such, it is important to select the right electric forklift manufacturers for your needs. This article explores the various aspects of choosing the best electric forklift manufacturers to meet your requirements.

China Forklift Manufacturer - Kinlift

Kinlift is one of the leading China forklift manufacturers that offers a wide range of high-performance forklifts. Their reliable, durable and affordable products have gained them immense recognition in the market. They have established a strong presence in both Chinese and international markets for their superior quality standards and competitive pricing. Kinlift uses advanced production technologies to create efficient, reliable and cost-effective forklifts suitable for various applications.