Guide for electric stacker truck

Application guide for electric stacker truck

This application guide is for electric stacker trucks.

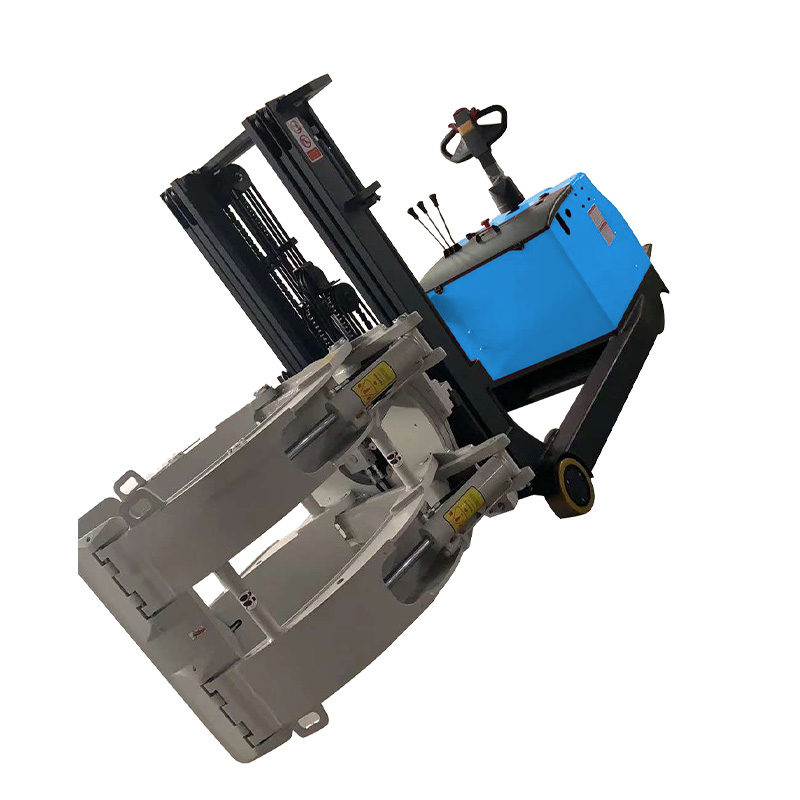

Electric stacker trucks are used to move and stack pallets in warehouses and other storage facilities. They are powered by batteries, which makes them environmentally friendly and quiet to operate. Electric stackers have many features that make them ideal for use in warehouses, including:

- They are very maneuverable, so they can be used in tight spaces.

- They have a low center of gravity, so they are stable when stacked with heavy loads.

- They have a built-in charger, so there is no need to connect them to an external power source.

- They are easy to operate, with controls that are similar to those on a forklift.

Precautions for using electric stacker truck

Electric stacker trucks are becoming increasingly popular in industrial and commercial settings. They offer a number of advantages over traditional forklifts, including increased maneuverability, lower noise levels, and zero emissions. However, electric stacker trucks also come with their own set of safety concerns.

Here are a few tips for safely using an electric stacker truck:

- Read the manual before operating the truck. Familiarize yourself with the controls and learn how to properly use them.

- Inspect the truck before each use. Check for any damage or wear and tear that could affect its performance.

- Never exceed the weight limit for the truck. Overloading it can damage the lift mechanism and make it more difficult to control.

- Wear proper safety gear when operating the truck, including closed-toe shoes, long pants, and a hard hat.

- Keep your hands and feet clear of moving parts while the truck is in operation.

Common faults and solutions of electric stacker truck

1. Faulty contactor

If the stacker truck doesn’t move when the buttons are pressed, it may be due to a faulty contactor. The contactor is an electrical switch that’s used to control the flow of electricity to the stacker truck’s motor. Over time, the contacts in the contactor can become worn and no longer make a good connection. This will prevent electricity from flowing to the motor, and as a result, the stacker truck won’t move.

To test whether or not the contactor is faulty, use a multimeter to test for continuity across the contacts. If there is no continuity, then the contactor will need to be replaced.

2. Faulty motor

Another common problem with electric stacker trucks is a faulty motor. If the stacker truck’s motor is not working properly, it will prevent the stacker truck from moving. There are a few ways to test whether or not the motor is faulty. First, you can use a multimeter to test for continuity across the terminals of the motor. If there is no continuity, then the motor is most likely

1. The stacker truck cannot be turned on:

Check whether the power supply is turned on, whether the fuse is blown, and whether the power cord is connected.

2. One of the four wheels of the stacker truck does not rotate:

Check if there is something blocking the wheel; if so, remove it. If not, check if the motor of this wheel is damaged.

3. The electric stacker truck moves slowly:

First check if the battery is running out of power and needs to be recharged; second, check if there is something blocking the wheels; third, check whether the motor has been damaged.