Application guide about electric pallet lift

Application guide about electric pallet lift

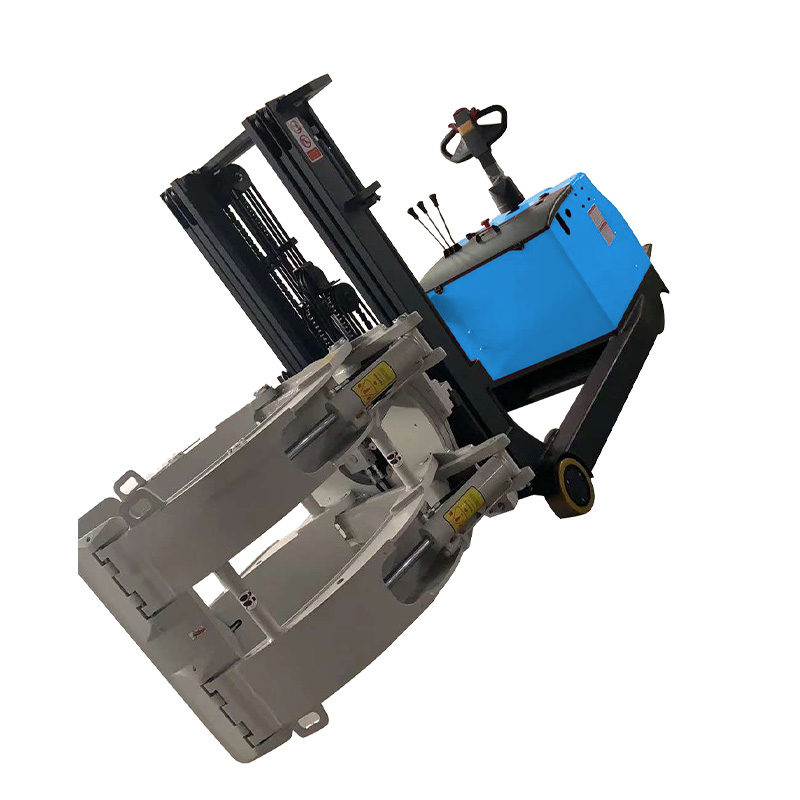

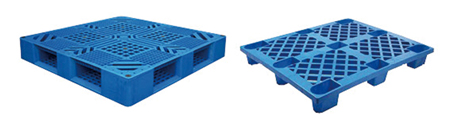

An electric pallet lift truck is a type of powered industrial truck that is used to move heavy loads from one location to another. These trucks are commonly used in warehouses and factories to move pallets or other heavy loads from one point to another. Electric pallet lift trucks are typically powered by batteries, which makes them environmentally friendly and allows them to be used in a wide variety of settings.

An electric pallet lift is a type of forklift that is used to move pallets from one location to another. They are commonly used in warehouses and factories to move heavy loads of products or materials. Electric pallet lifts are powered by batteries, which makes them environmentally friendly and very efficient.

If you are thinking about purchasing an electric pallet lift, there are a few things that you need to know before making your purchase. This guide will provide you with everything you need to know about electric pallet lifts, including their benefits, features, and how to choose the right one for your needs.

Precautions for using electric pallet lift

Here are some tips for using an electric pallet lift:

- Always wear gloves when handling the lift.

- Make sure the area around the lift is clear of obstacles.

- Do not exceed the weight limit for the lift.

- Do not use the lift if it appears to be damaged in any way.

1. Read the manufacturer's instructions carefully before using the electric pallet lift.

2. Inspect the lift and its components for damage before each use. Do not use the lift if it is damaged.

3. Make sure that the work area is clear of obstacles before using the lift.

4. Keep your hands and feet away from moving parts while the lift is in operation.

5. Never attempt to move or adjust the load while the lift is in operation.

6. Use caution when moving the load on or off of the lift, as it may be unstable during this time.

Common faults and solutions of electric pallet lift

stacker

1.The electric pallet lift stacker cannot be raised or lowered, and the display shows "E01":

This is caused by a failure of the power supply system. The solutions are as follows:

(1) Check whether the power switch is turned on, whether the power indicator is on, and whether the fuse is blown;

(2) Check whether the contactor coil is electrified;

(3) Check whether there is voltage at both ends of the motor; if not, check whether the motor or its wiring is faulty;

(4) If there is voltage at both ends of the motor, check whether the motor itself or its drive circuit board are faulty.

2.The electric pallet lift stacker cannot be raised or lowered, and the display shows "E02": This is caused by a failure in the control system. The solutions are as follows: (1) Check whether the control handle switch is turned on; (2) Check for loose wiring harnesses in both control boxes; (3) Check if any of the buttons on the control panel are

stacker

1. Faulty drive motor

If the drive motor is faulty, it will not be able to provide the power needed to move the pallet lift stacker. This can be caused by a number of factors, such as a loose connection, a blown fuse, or a damaged wire.

Solution: Check all connections and fuses, and replace any damaged wires. If the problem persists, the drive motor may need to be replaced.

2. Faulty control board

The control board is responsible for controlling all of the electrical components of the pallet lift stacker. If it is faulty, it can cause problems with the operation of the lift stacker.

Solution: Check all connections and fuses, and replace any damaged wires. If the problem persists, the control board may need to be replaced.