Application of stacking pallet jack

Application of stacking pallet jack

One common use for stacking pallet jacks is in warehouses. They can be used to move large quantities of inventory from one location to another, or to stack it in specific areas. This helps keep your warehouse organized and makes it easier to find items when you need them.

Another common use for stacking pallet jacks is in retail stores. They move heavy boxes of merchandise from the back room to the sales floor, or stack them in specific areas of the store. This helps store associates organize their merchandise and makes it easier for customers to find what they're looking for.

Precautions for the use of stacker trucks

If you're using a stack pallet jack, there are a few things you should keep in mind. First, make sure the load is evenly distributed across the pallet. Second, be sure to grab the handles with both hands and keep your back straight as you lift the tray off the ground. Finally, when you lower the tray back to the ground, do so slowly and carefully.

1. Read the manual and familiarize yourself with the controls. Before using a pallet jack, take some time to familiarize yourself with the machine and how it works.

2. Inspect the pallet jack before use. Every time you use your pallet jack, you should inspect it for damage or wear that could cause problems. Check the wheels, steering system and hydraulic system for any signs of damage or leaks.

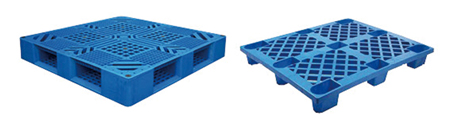

3. Select the correct size pallet jack for the job. There are different sizes of pallet jacks for different types of loads. Make sure the jack you choose is suitable for the weight of your load and will fit your pallet.

4. Position the load correctly on the pallet jack. Before attempting to move a load, make sure it is properly positioned on the pallet jack. The load should be centered on the platform and not extend beyond the edge of the platform or beyond the reach of the forks.

5. Be careful when moving loads up or down ramps. When moving a load up or down a slope, be careful not to tip over backwards or forwards while advancing.

Common faults and solutions of stacker

Common malfunctions:

- Fault: Pallet jacks cannot be stacked.

Solution: Check if the quick release valve is blocked. If not, there may be a problem with the air filter or air regulator.

- Malfunction: The pallet jack is unstable.

Solution: Check that all four support legs are locked in place. If not, tweak them until they are.

- Malfunction: Pallet jack will not move forward or backward.

Solution: Check whether the drive wheel is blocked. If not, there may be a problem with the drive motor or belt.

1. Pallet failure: Check whether the pallet is damaged and whether the load is evenly distributed.

2. The load is too high: Check whether the load is too high and whether it is properly balanced.

3. Jack is not level: Check that the jack is level and the wheels are properly inflated.

4. Seized Wheels: Check the wheels for debris or damage and clean or replace as necessary.

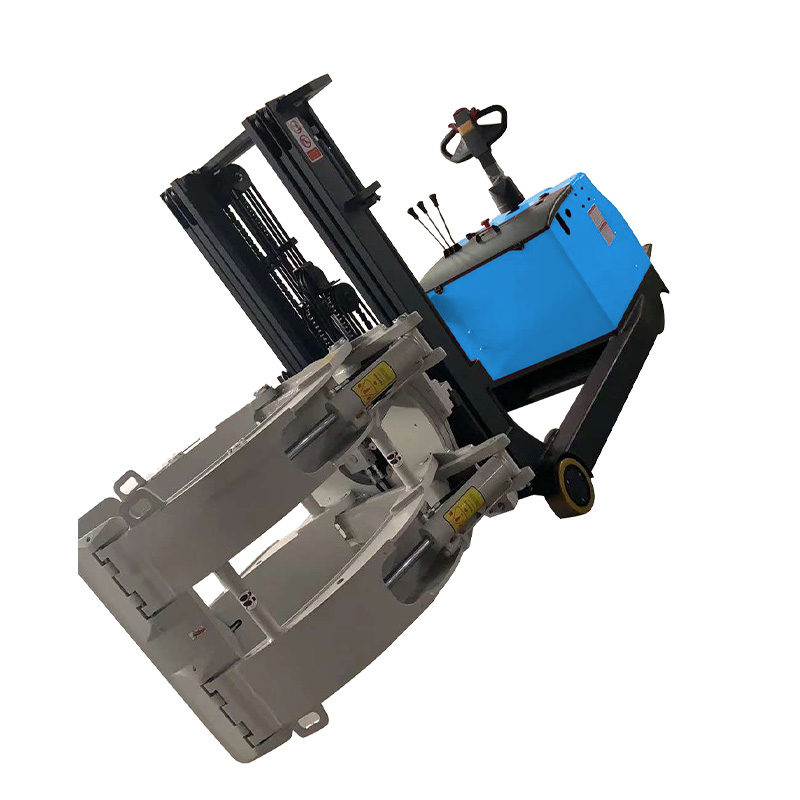

Efficient material handling is critical for businesses aiming to optimize operations and achieve higher levels of productivity. It includes the movement, storage and control of goods at all stages of production or distribution. An important tool to simplify the material handling process is the stacking pallet jack, and Kinlift can help you solve this problem.