Application guide for walkie pallet stacker

Application guide for walkie pallet stacker

This is a guide for how to apply for a walkie pallet stacker.

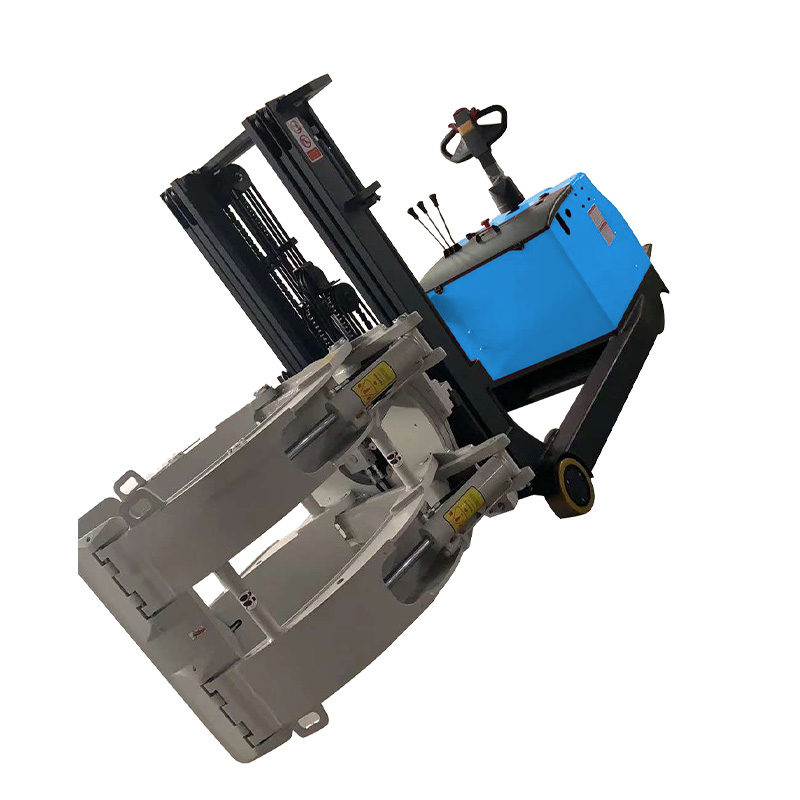

A walkie pallet stacker is a type of material handling equipment used to move and stack pallets. Walkie pallet stackers are powered by batteries, and can be operated by a single person. They are typically used in warehouses and other industrial settings.

1. Before using a pallet stacker, always consult the user manual to ensure you understand how to properly and safely operate the equipment.

2. When choosing a pallet stacker, consider the type of application it will be used for. Some pallet stackers are better suited for certain tasks than others.

3. Always inspect the pallet stacker before use to ensure that it is in good working condition and that there are no loose parts or damaged components.

4. Be sure to wear proper safety gear when operating a pallet stacker, including gloves, safety glasses, and closed-toe shoes.

5. When loading or unloading a pallet onto a stacker, be sure to keep your hands and fingers clear of any moving parts to avoid injury.

Notes on using walkie pallet stacker

Here are some tips on using a walkie pallet stacker:

- When loading or unloading a pallet, make sure the forks are properly positioned.

- Do not attempt to move a pallet if it is not properly secured.

- Be careful when moving around corners, as the load may shift and cause the stacker to tip over.

When using a walkie pallet stacker in your warehouse, there are a few things you need to keep in mind.

First, always make sure that the area around the pallet is clear and free of obstacles.

Second, when lifting or lowering the pallet, do so slowly and carefully to avoid damaging the goods on the pallet or injuring yourself.

Finally, when moving the pallet around, be aware of your surroundings and keep an eye out for potential hazards.

Common faults and solutions of walkie pallet stacker

1.The stacker doesn’t move or is difficult to move

This is generally caused by the transmission chain being too tight or too loose, and the solution is to adjust the tension of the transmission chain. If the tension of the transmission chain is not adjustable, it may be that the reducer oil is insufficient, and new oil should be added; if it still doesn’t work, it means that there is something wrong with the reducer, and it needs to be sent to a professional maintenance point for repair.

2.The stacker moves but cannot lift or descend goods

Generally speaking, this kind of problem is caused by too little pressure in the hydraulic system. The solution is to add hydraulic oil; if adding hydraulic oil does not solve the problem, it means that there is a problem with one of the hydraulic valves, and it needs to be sent to a professional maintenance point for repair.

3.The stacker moves up and down when lifting goods, and suddenly stops during movement

This kind of situation usually indicates that there is air in the hydraulic system. The solution is to release air

1.The drive wheel skids

This is because the driving force is too large or the traction is poor, so that the wheel slips. The solution is to reduce the driving force or increase the traction.

2. Stacking objects are unstable and easy to fall

This is because the stacking height is too high, or the stacking surface is not level enough, so that the center of gravity of the stacking object is unstable and easy to fall. The solution is to lower the stacking height or make the stacking surface more level.

3.The armrest moves up and down during lifting and lowering, causing impact noise at both ends of movement

The reason may be that there are foreign objects in the guide rail slot or that something has been stuck in it, which makes it difficult for the carriage to slide smoothly; Or it may be that there is something wrong with